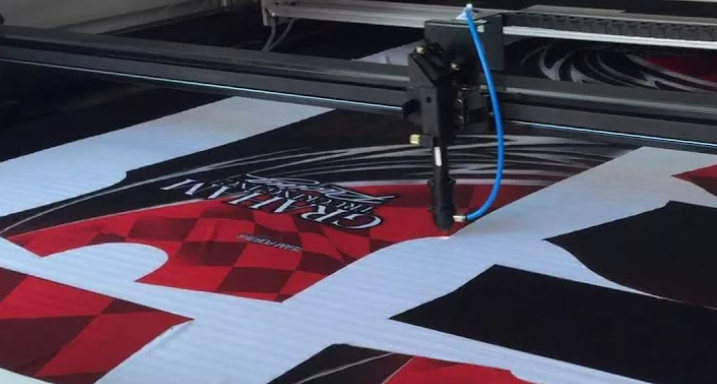

Color-Managed Precision

Our color-managed workflow uses spectrophotometry and ICC profiling to align your files to the printer and substrate gamut. This technical pipeline reduces guesswork: proofs are scanned, target profiles are applied, and patch charts verify density before production. The result is repeatable color fidelity whether you run a single prototype or a thousand-piece order. We also offer soft-proof previews and physical swatches so that designers can approve final tones. This system minimizes rework, shortens lead times, and raises confidence that the product you imagined will be the product delivered.